Checking the hydraulic lifters

1. Start the engine and let it run, until the radiator fan starts on a petrol engine, a diesel engine – the oil temperature will not reach at least 80 ° C.

2. Run the engine to 2500 rpm. If the valve lifters are still noisy, stop the engine and, after it has cooled down, proceed as follows.

3. Remove the engine cover, then the cylinder head cover. and on some engines also the top of the intake manifold. In four-cylinder engines, you still need to remove the ignition coils, do not forget to disconnect the ground cable). Then remove the air filter housing guides and the upper toothed belt cover. Finally, remove the crankcase ventilation hose, unscrew the fastening screws and remove the cover. On a V6 engine, you need to unhook the head cover latches, unscrew the screws of both covers and remove the covers. Also for diesel engines, undo the screws and remove the covers.

4. Turn the crankshaft clockwise so, the cam of the cam follower to be checked is facing up. To turn the shaft, engage fourth gear and push the car, or attach a ratchet wrench to the shaft pulley bolt.

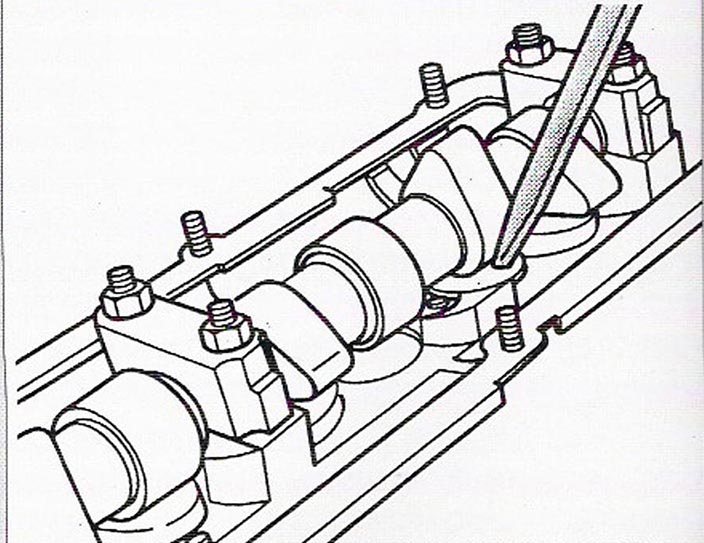

5. Measure the clearance between the cam and the follower plate. If the play is greater than 0,20 mm on a gasoline engine and 0,10 in a diesel engine, replace the hydraulic tappet with a new one. When there is less or no play, then press down the pusher with the wedge. If now you can insert the plate 0,20 mm feeler gauge between cam and follower, it is also replaceable. In a diesel engine, replacement of the tappet is necessary, if you feel idle movement while pressing it until the valve opens, bigger than 0,10 mm. After installing the new pusher, the engine cannot be started for approx. 20 minutes. Its hydraulic balancing elements must first line up (otherwise the valves may strike the piston).

When checking, press down the pusher plate with a plastic or wooden wedge. Do not use metal bars, because you will damage the surface of the pusher plate.

6. When installing the cylinder head cover, check the condition of the gasket and replace it if necessary. On a 6-cylinder engine, the gasket on both sides must be lubricated with silicone D 007 000 04. On four cylinder engines, you will need some sealant in the following places: both edges of the contact surfaces of the bearing seats and the head as well as the timing gear and head adjuster. Apply sealant carefully with a small screwdriver.

7. The cylinder head cover nuts on all engines must be tightened very carefully.