Hydraulic tappets

Hydraulic tappets

The increase in engine temperature is accompanied by a change in dimensions (elongation) hot parts. That is why clearance is necessary, e.g.. between the camshaft and the follower plate. Without the necessary clearance, the valves could become leaky. Valve clearances in older engine designs must be regularly checked and adjusted. In Golf engines, hydraulic lifters take over the task of adjusting the valve lashings, which are maintenance-free. A damaged valve tappet makes itself felt by a rattling noise, which can also occur with operational hydraulic tappets, if:

■ There is still too little oil in the system shortly after the engine has been started. This can happen after the car has been parked for a long time;

■ the car was overloaded at high outside temperatures,

■ If the oil level is too low, the oil pump draws in air.

If the rattle of the valves subsides after an extended ride, but will reappear when driving around town for short distances, it will be necessary to replace the oil drain shut-off valves. To replace a damaged hydraulic tappet (the entire component is replaced) it is necessary to remove the camshaft. This is only for the workshop. On your own, you can check the operation of the hydraulic tappets. This requires a flat feeler gauge and a wooden or plastic wedge.

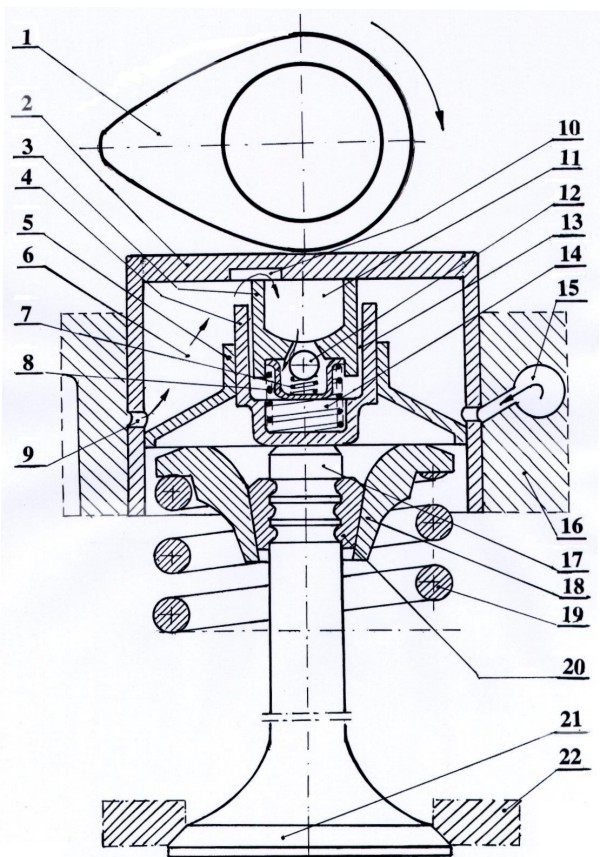

How a hydraulic pusher works?

The hydraulic lifter is connected to the engine lubrication system. The amount of oil in the lower chamber of the pusher, on which the plunger rests, is variable. In this way, different valve clearance values can be compensated for. With the valve closed, the oil pressure between the two chambers is equalized. The plunger spring pushes it upwards. There is no play between the cam and the valve lever. When the cam hump begins to press against the lever, the plunger is pushed down, whereby a high oil pressure is built up in the lower chamber. Pressure forces and springs push the ball upwards, which closes the flow of oil between both chambers. The piston now rests on the created hydraulic cushion of the lower chamber. The hydraulic valve lash reset acts as a rigid element, on which the valve lever rests. The thrust of the cam can now be transferred to the valve, which opens. After the cam has come off the valve lever, the ball opens the connection of both chambers and the oil pressure can equilibrate.