Elements of the cooling system:

Elements of the cooling system:

Coolant pump. Centrifugal pump, for continuous circulation of the coolant. Depending on the type of engine, the pump is driven by a V-belt or a toothed belt from the crankshaft.

Cooler. It consists of two plastic tanks, located on the left and right sides. The tanks are connected by thin-walled tubes, forming a network on a scaffolding made of gill. As a result, the total area covered by the air is several square meters. The radiator is attached at two points at the top and bottom to the body crossmember.

Thermostat. Keeps the coolant temperature constant. It opens at a temperature of approx. 87° C and allows the fluid to flow to the radiator or back to the engine. Inside the thermostat there is a sleeve filled with a special wax and a mushroom-shaped valve. As the coolant temperature increases, the wax becomes liquid, it increases in volume and gradually opens the valve controlling the supply of chilled liquid from the cooler. The valve is fully open at engine operating temperature, thus, a shortened liquid circulation is not possible. If the liquid cools down too much, the spring presses down on the valve plug and blocks the flow through the radiator for as long, until the coolant reaches the correct temperature again.

On four-cylinder engines, the thermostat is located at the bottom of the engine next to the coolant pump, and on six-cylinder engines – on the front of the engine block between the cylinder banks.

Expansion tank. The pressure in the cooling system is too high, Coolant vapor escapes through the valve in the tank cover. A dedicated expansion tank is used in all engines. There is a coolant level indicator in its wall. The tank is located in the engine compartment on the right-hand side (looking in the direction of travel).

Radiator fan. The radiator is additionally cooled by a fan. In some trim levels of the car, two fans are installed.

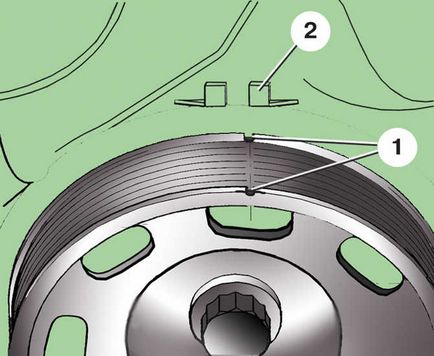

Setting the piston 1. cylinder at TDC

Setting the piston 1. cylinder at TDC