Compression pressure

Compression pressure

In order to establish the technical condition of the engine, the compression pressure in each cylinder should be checked. High pressures are built up in the combustion chamber when the air / fuel mixture is burned, in gasoline engines up to 6 MPa. This means heavy loads on the pistons, piston rings, cylinder walls, valve seats and seals. A leak in the combustion chamber causes increased oil and fuel consumption, deterioration of exhaust gas composition, reduced power and difficult starting of a cold engine. If such symptoms appear, then measuring the compression pressure will help to determine the cause of the fault.

In gasoline engines, the compression pressure values in individual cylinders should not differ by more than 0 0,3 MPa, and in diesel engines, at most o 0,5 MPa.

When in one or more cylinders, the differences are greater, it is a malfunction, which may be caused by the wear of many different components.

Compression pressure guidelines.

The compression pressure values are different for gasoline and diesel engines. Approximate values given in the table refer to engines in good technical condition. It is also worth remembering, that absolute values of compression pressure should not be taken to assess the condition of the engine. It is more important, that the pressure is the same in all cylinders, and any differences did not exceed 0,2 MPa.

Compression pressure required – Volkswagen Golf 4 – Bora

| Type of engine | Engine type | Normal pressure – Minimum allowable stress in MPa | |

| Gasoline

four cylinders |

AHW,AKQ,APE,

AXP, ATN, THE END dead, AKL, APF APK, AQY AGN |

1,0 – 1,5

1,0 – 1,5 1,0 – 1,3 1,0- 1,3 0,9 -1,4 |

0,70

0,70 0,75 0,75 0,75 |

| Turbocharged four-cylinder gasoline engine | AGU, AQA, SUPPLY | 1,0 – 1,4 | 0,70 |

| Gasoline five-cylinder | MEMBER | 0,9 . 1,2 | 0,70 |

| Gasoline five-cylinder | AQP | 0,9 . 1,4 | 0,70 |

| Diesel | AGR, AHF, ALH, AQM | 2,5 – 3,1 | 1,90 |

The compression pressure drops with the age of the engine, therefore the values are smaller, but the same in all cylinders is normal. Only when the pressure value drops below the permissible minimum value, you can start considering replacement, or repair the engine. Pressure differences greater than 0,3 MPa in gasoline engines and 0,5 MPa in diesel engines, indicate one of the following reasons:

– wear on pistons or piston rings,

– Seizure of the rings due to deposition of combustion residues,

– distortion of the cylinders due to seizure of the pistons,

– precipitation from oil and exhaust gas deposits on valve stems and seats,

– curvature of the valves,

– valve burnout (due to too little play).

You can measure the compression pressure yourself, if a suitable measuring instrument is available. For gasoline engines, it can be purchased for little money in a specialized store. Volkswagen recommends a special compression pressure tester V.A.G. 1763 for all engines (an adapter is also required for diesel engines 1381/12). Only the indications of such a meter can be relied on. With other instruments, we can only measure the differences between individual cylinders. You will also need a V.A.G spark plug wrench to perform the measurements. 3122 B and torque wrench V.A.G. 1331 for gasoline engine and articulated V.A.G. 3220 for diesel incandescent lamps.

The help of a second person is essential during the measurements, which will actuate the starter and move the accelerator pedal (You must operate the measuring instrument). In order for the compression pressure measurement to be accurate, make sure, that the hydraulic lifters are working properly, and the starter is serviceable, workshops that rent workstations for DIY enthusiasts have compression pressure gauges, and sometimes also cylinder pressure loss testers, which make it possible to determine the cause of pressure loss.

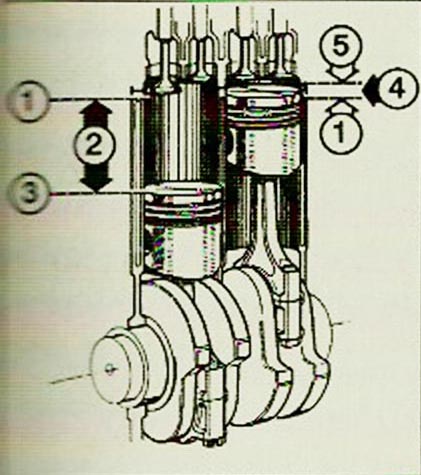

Displacement – (2) covers the cylinder space between TDC (1) a DMP (3) plunger. Combustion chamber (4) is the space between the recess in the cylinder head (5), with the piston crown in TDC position (see plunger on the right)

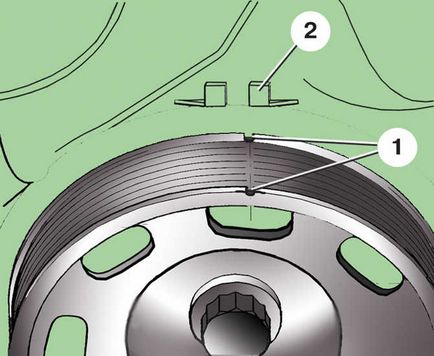

Displacement – (2) covers the cylinder space between TDC (1) a DMP (3) plunger. Combustion chamber (4) is the space between the recess in the cylinder head (5), with the piston crown in TDC position (see plunger on the right) Setting the piston 1. cylinder at TDC

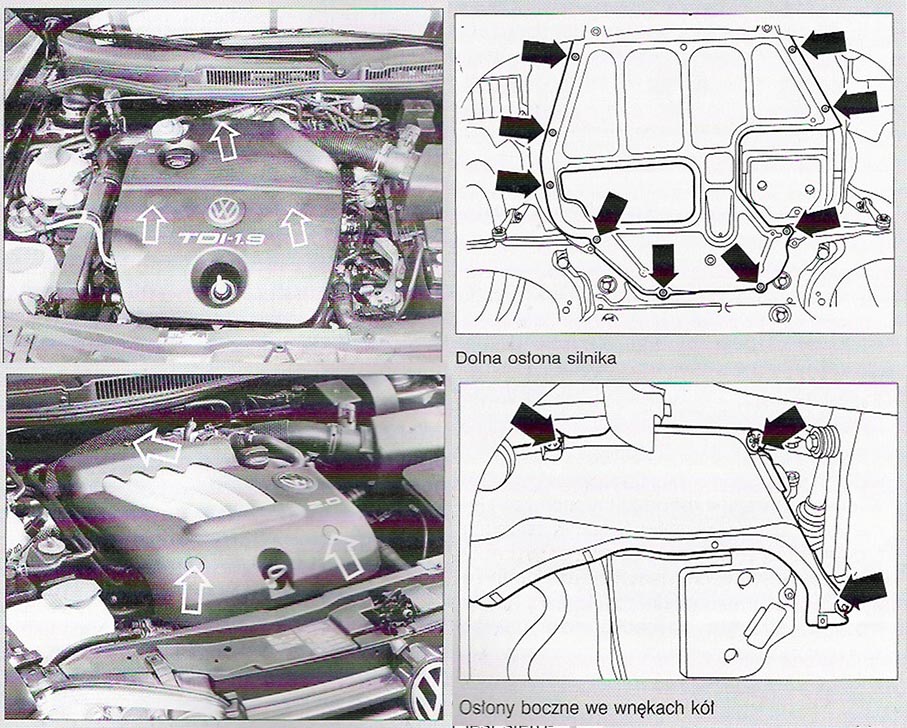

Setting the piston 1. cylinder at TDC Golf and Bora car engines are covered with various plastic covers. You must remove these covers before doing most work on the engine. In gasoline engines, the top covers are mainly used for aesthetics, and in diesel engines also a lower noise level. A large plate under the engine is to suppress noise and show aerodynamics.

Golf and Bora car engines are covered with various plastic covers. You must remove these covers before doing most work on the engine. In gasoline engines, the top covers are mainly used for aesthetics, and in diesel engines also a lower noise level. A large plate under the engine is to suppress noise and show aerodynamics.