Oils in Mazda 3.

Mazda engines run well with good oils. Mineral ones finish off the unit quite quickly… Synthetic or semi-synthetic oils should be used. They are replaced every 10,000 km (along with the filter in DiTD, in the case of MZR-CD every 20,000 km). Extending this period is inappropriate not only for the engine but also for the turbine. Common rail engines have less frequent oil change intervals.

Mazda's branded oil is DEXELIA, or French ELF. For example, my friend magicadm uses Elf SXR 5W30 (course 140 thousand km – no cavities), (ex)my madzia DiTD is using Shell Helix Diesel semi-synthetic again (mileage approximately 200kkm or more )

CR engines receive different oil – service pours Mobil Super FE 5w30 (semi-synthetic oil?), sometimes called Mobil Special FE 5w30. Other websites only offer Dexelia – who's right, hard to say. In M6, replacement is theoretically carried out every 20,000 km, but it's probably better to shorten the operating time – an overfilled oil filter may have trouble keeping the oil clean, which may result in gluing the dragon…

For CR engine 110/143 DPF installed, among others, in M5 and M6, ONLY oils intended for engines with a particulate filter may be used (the filter costs money, I guess 9 kpln, so you better take care of it). Dexelia DPF is not the same as Elf DPF, because Mazda wanted three times lower content of substances in the oil that are harmful to DPF – and this oil is available only at Mazda Dealerships.

Poor oil and filter (and even more so, their replacement is too rare) they very often cause seizing (peeling) camshaft (most often on the first cam). This phenomenon does not only apply to Mazda engines, but also to other companies

Two sample photos taken in a Mazda with quite low mileage but poor service – filters replaced every other time, oil – as long as it's cheaper “it's just oil”…

Additionally (probably) overpowering a cold engine causes greater load on the valves and, consequently, – worse lubrication of the roller in the head (the oil is still too cold and too thick) which may additionally result in reduced shaft life. Similar effects can be observed (although less often) in RF5C engines – i.e. models with M6 ysz We recommend using Castrol Magnatec oil in cars with several years of experience (DiTD, CD) as many people have had some rather strange complications after using it.

In this case, the camshaft must be replaced with a new one – roller cost approx. PLN 450 (available on the website – e.g. The car).

You can't (I guess, but I definitely wrote it wrong) use motodoctor type oil additives.

Problems, the source of which was a sealed oil dragon. We have not been able to discover clearly why this happened, but you have to keep this in mind, when we have the so-called. “snake in your pocket” for filter or oil… In the history of the automotive industry, a thesis straight from toddlers has been put forward many times, poldków and “Russian pogroms” with a national nickname “Warsaw”, that over time (along with the mileage) increasingly thicker oils should be used (read mineral). First of all, this is bullshit (when it comes to use in Mazdas) and secondly, it is nonsense when it comes to today's times. If someone bought a Mazda filled with mineral oil, don't ask what to do, just let him exchange it for “semi-synthetic engine lubricant”. Many people have performed this procedure with very positive results. If the engine is not completely damaged, it will not have any negative side effects. If the engine is dying, nothing will help it except overhaul… Operating Mazdas with a mineral engine results in the oil rings seizing up in the pistons very quickly.

Oil blackening is a common situation in indirect injection engines (After a minute of running the engine, the clean oil will be black and this is normal). This will no longer be the case with CR engines – Due to the more complete combustion of the fuel, the oil does not have to dissipate such amounts of soot existing on the cylinder walls. Direct injection engines are about half the curve

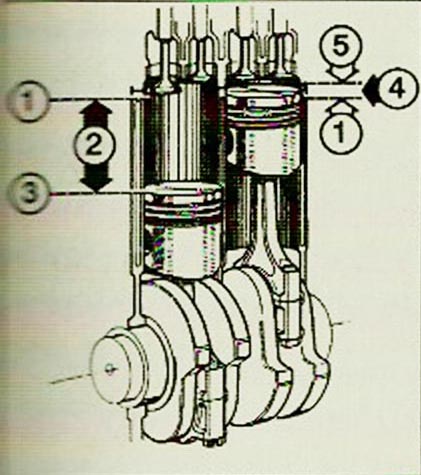

Displacement – (2) covers the cylinder space between TDC (1) a DMP (3) plunger. Combustion chamber (4) is the space between the recess in the cylinder head (5), with the piston crown in TDC position (see plunger on the right)

Displacement – (2) covers the cylinder space between TDC (1) a DMP (3) plunger. Combustion chamber (4) is the space between the recess in the cylinder head (5), with the piston crown in TDC position (see plunger on the right)